24A sprockets

Description

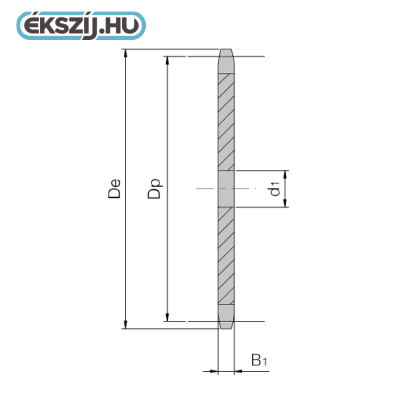

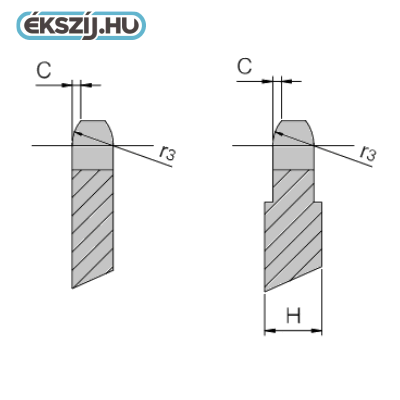

The 24A flat sprockets are hubless, toothless sprocket types suitable for driving roller chains with markings matching their name. Sprockets can be one, two, or three-row, which by definition can be used for one-, two-, or three-row roller chains of the same type. The table below shows the chain type, number of teeth and outer diameter. For more information, use the catalogs on the Downloadable documents tab.

Pitch: 1.1/2", 38.1mm

Sprockets are manufactured according to DIN 8187 and ISO R606, in C45 (K1045) material. Sprockets made by different manufacturers may differ in certain production parameters, but their main parameters are similar or the same. In normal use, identical sprockets made by different manufacturers are interchangeable!

Is a sprocket with hardened teeth or a sprocket with non-hardened teeth better?

This is such an issue as the case of chicken and eggs. Some swear by sprockets with hardened teeth, others by untrained ones. To put it simply, in the case of sprockets with non-hardened teeth, the sprocket usually wears out first, while in the case of sprockets with hardened teeth, the roller chain needs to be replaced more often. It is up to the user to choose which product is cheaper or easier to replace on the machine for a given application. Hardened tooth sprockets are currently not available in the assortment of our webshop.

Why should I use sprocket drive?

One of the simplest and oldest positive coupling drives. You can easily change the transmission rate (by changing the size of the chain). It is also capable of driving back and forth. It is not significantly disturbed by dirt and ambient temperature. It requires relatively little maintenance. It does not require special knowledge to use. So because it's simple, requires little care, and is relatively cheap.