Motor slides for electric motors

General information

The electric motor mounting base, also known as the motor slide, is a structure made of steel plate that enables easy movement of the motors of the electric motors, regardless of the size of the electric motor. By using an electric motor sliding foot, it becomes easy to install, replace or re-tension the driven V-belt or roller chain.

General information

The electric motor mounting base, also known as the motor slide, is a structure made of steel plate that enables easy movement of the motors of the electric motors, regardless of the size of the electric motor. By using an electric motor sliding foot, it becomes easy to install, replace or re-tension the driven V-belt or roller chain.

In all cases, the size of the motor slide corresponding to the housing size of the electric motor!

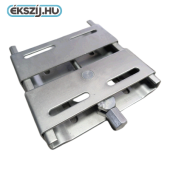

Motor slides

The fastest and most economical method of securing motors to machine beds. The five sizes are manufactured from cold rolled steel and then galvanised. They can accommodate motor frame sizes 63 to 180 and have four slotted holes for fastening the base to the foundation. The pressed top plate is designed to slide over the base plate preventing vibration and noise whilst ensuring continuous belt alignment. Belts are tensioned by adjusting a single screw. The motor is bolted to the two piece top plate which accommodates a wide range of motors. Centre distance adjustments can be made without the need to loosen the motor bolts.

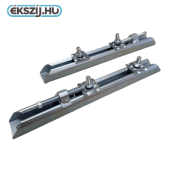

Slide Rails

Covering frame sizes 63 to 225, Challenge slide rails are manufactured in galvanised steel with movable positioning blocks for rapid accurate drive alignment. The pressed steel rails are solidly fixed by three securing bolts while the motor is bolted to the rails eradicating vibration and noise whilst ensuring rigid positioning.The motor is bolted to the slide rails and positioned with the aid of adjustment screws. The motor must be stopped and the motor bolts loosened before repositioning.

In all cases, the size of the motor slide corresponding to the housing size of the electric motor!

Motor slides

The fastest and most economical method of securing motors to machine beds. The five sizes are manufactured from cold rolled steel and then galvanised. They can accommodate motor frame sizes 63 to 180 and have four slotted holes for fastening the base to the foundation. The pressed top plate is designed to slide over the base plate preventing vibration and noise whilst ensuring continuous belt alignment. Belts are tensioned by adjusting a single screw. The motor is bolted to the two piece top plate which accommodates a wide range of motors. Centre distance adjustments can be made without the need to loosen the motor bolts.

Slide Rails

Covering frame sizes 63 to 225, Challenge slide rails are manufactured in galvanised steel with movable positioning blocks for rapid accurate drive alignment. The pressed steel rails are solidly fixed by three securing bolts while the motor is bolted to the rails eradicating vibration and noise whilst ensuring rigid positioning.The motor is bolted to the slide rails and positioned with the aid of adjustment screws. The motor must be stopped and the motor bolts loosened before repositioning.

News

2026.01.10.-én az ügyfélszolgálat szünetel

A rendelések feldolgozása, a csomagfeladás és az ügyfélszolgálat szünetel. Webáruházunk nyitva tart, a rendelések leadása lehetséges!

next

2026.01.10.-én az ügyfélszolgálat szünetel

A rendelések feldolgozása, a csomagfeladás és az ügyfélszolgálat szünetel. Webáruházunk nyitva tart, a rendelések leadása lehetséges!

next

Hello 2026! Újra itt vagyunk!

2026. január 5-től újra teljes erőbedobással munkába álltunk! Várjuk kedves vásárlóinkat! A bejegyzésben néhány általános infót közlünk a 2026-os szállításokkal kapcsolatosan...

next

Hello 2026! Újra itt vagyunk!

2026. január 5-től újra teljes erőbedobással munkába álltunk! Várjuk kedves vásárlóinkat! A bejegyzésben néhány általános infót közlünk a 2026-os szállításokkal kapcsolatosan...

next

Téli leállás 2025

Rendelések leadása lehetséges, de a rendelés feldolgozás, az ügyfélszolgálat és a csomagfeladás szünetel 2026. január 5-ig!

next

Téli leállás 2025

Rendelések leadása lehetséges, de a rendelés feldolgozás, az ügyfélszolgálat és a csomagfeladás szünetel 2026. január 5-ig!

next

Ünnepi nyitvatartás

Az ekszij.hu webáruház folyamatosan elérhető az ünnepi időszakban, a leadott megrendeléseket is fogadjuk, azonban az csomagfeladás és az ügyfélszolgálat 2025. december 19-én 17 órától 2026. január 5. reggel 8 óráig szünetel.

next

Ünnepi nyitvatartás

Az ekszij.hu webáruház folyamatosan elérhető az ünnepi időszakban, a leadott megrendeléseket is fogadjuk, azonban az csomagfeladás és az ügyfélszolgálat 2025. december 19-én 17 órától 2026. január 5. reggel 8 óráig szünetel.

next